Metal cable trays are an essential component of modern electrical infrastructure, offering a safe, efficient way to route and support cables. Used extensively across residential, commercial, and industrial projects worldwide, including key markets like Dubai, metal cable trays have become indispensable in cable management. With cable tray suppliers in Dubai meeting the region’s growing demand, these trays have gained popularity today. Yet, the journey from invention to widespread use is a relatively recent one, closely tied to advancements in electrical safety and efficiency.

Early Electrical Infrastructure and Cable Management Challenges

In the early days of electrical systems, managing cables was challenging and often hazardous. Most cables were either enclosed in conduits—rigid tubes through which cables were threaded—or laid directly along the ground or floor. Both methods presented limitations. Conduits, while offering some protection, restricted access to the cables, making installation and maintenance difficult and time-consuming. Electricians often had to pull cables through these tubes manually, which could be a complex, labor-intensive process, especially in larger installations. For cables laid along floors or in walls, accessibility was somewhat easier, but this practice posed significant safety hazards, increasing the risk of tripping, damage to cables, or even fire.

Electricians also faced challenging working conditions. Installing or repairing cables often required crawling into cramped, dark spaces under floors or between walls, where they risked injury. These methods were inefficient and caused significant disruption to the surrounding environment, often requiring work to halt in areas near the installation site.

Saul Halpern’s Revolutionary Invention in the 1940s

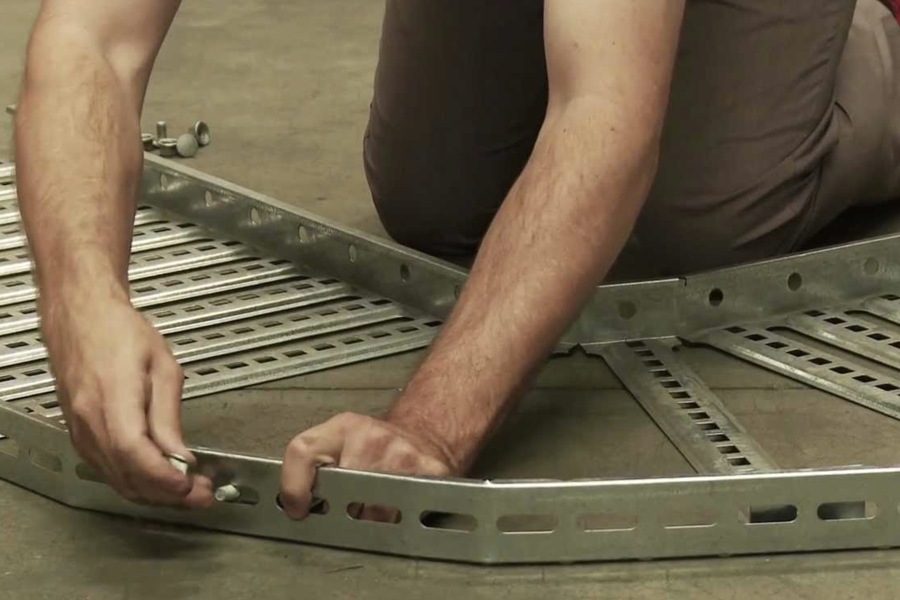

In the 1940s, the electrical industry experienced a pivotal innovation in cable management thanks to an electrician named Saul Halpern. Observing the limitations of existing methods, Halpern began experimenting with a new approach. He devised a wire basket structure that could be attached to walls or ceilings, creating a simple, elevated pathway for cables. This wire basket became the first metal cable tray, a design that addressed the issues of accessibility, safety, and efficiency.

Halpern’s invention allowed for easy installation and reconfiguration of cables, setting a new standard for cable management. Unlike conduits, which enclosed cables in a rigid tube, the open design of Halpern’s wire basket allowed easy access, making installation, maintenance, and repair of cables far simpler. This design innovation also provided more airflow around the cables, which was crucial for dissipating heat and reducing the risk of overheating, a common cause of electrical fires.

The Game-Changing Impact of Metal Cable Trays on the Electrical Industry

With its open, accessible design, the metal cable tray revolutionized cable management in the electrical industry. The tray’s structure meant electricians could quickly add, remove, or rearrange cables, which was especially beneficial for larger commercial and industrial setups that often needed to reconfigure electrical systems. The ease of access also facilitated quicker troubleshooting, reducing downtime and repair costs for businesses.

Another significant benefit of metal cable trays was their role in enhancing safety. Traditional conduits confined cables within closed pathways, which restricted airflow, potentially leading to overheating. The open design of cable trays promoted better ventilation, allowing heat to dissipate naturally and reducing the risk of fire—a particularly important feature in areas with high cable density or in warm environments.

Additionally, cable trays simplified code compliance. Regulatory agencies often require specific spacing and ventilation standards for electrical installations, especially in commercial and industrial facilities. Cable trays, with their accessible and organized layout, made it easier for installations to meet these standards, reducing the complexity of inspections and certifications.

Evolution of Cable Tray Materials and Design

As the electrical industry advanced, the design and materials of metal cable trays evolved to meet changing needs. Early trays were often made from basic metals, but as demand grew, manufacturers began exploring materials with enhanced durability and corrosion resistance. Modern cable trays are made from galvanized steel, stainless steel, and aluminum, materials that provide superior strength and corrosion resistance.

Each material offers unique advantages. Steel cable trays, for instance, are highly durable and are often used in industrial environments where they must support heavy loads. Galvanized steel provides additional corrosion resistance, making it suitable for outdoor and wet environments. Stainless steel, while more costly, offers excellent longevity and corrosion resistance, making it ideal for installations in harsh or corrosive environments, such as coastal areas or chemical plants. Aluminum, being lightweight and corrosion-resistant, is widely used in settings where weight is a concern, such as offshore platforms or high-rise buildings.

The design of cable trays has also diversified. Today, there are several types of trays, each serving a distinct purpose:

- Ladder Trays: These trays have a ladder-like design and are ideal for heavy-duty installations that require strong support and durability. The ladder rungs also provide additional support for larger cables and allow heat to escape easily.

- Perforated Trays: Featuring small holes in their base, these trays provide moderate support and ventilation, making them suitable for lighter cable loads.

- Wire Mesh Trays: Known for their flexibility and ease of installation, wire mesh trays are widely used in commercial applications where frequent changes to cable configurations are anticipated.

- Solid-Bottom Trays: These trays provide maximum cable protection and are often used in applications requiring shielding from external elements. However, they lack ventilation, which can lead to overheating in high-density cable configurations.

Metal Cable Trays as a Design Element in Modern Architecture

In recent years, metal cable trays have taken on a new role as a design element in modern architecture. Their sleek, industrial look has made them popular in open-ceiling designs, where exposed mechanical and electrical systems are part of the aesthetic. The open, minimalist structure of cable trays complements contemporary architectural styles and adds a functional yet stylish element to interior spaces.

By using metal cable trays as a visible design component, architects and interior designers can achieve a balanced blend of form and function. The trays not only serve their purpose in organizing cables but also contribute to the visual appeal of the space, adding a sense of modernity and sophistication.

The Significance of Metal Cable Trays in Modern Infrastructure

Since their invention by Saul Halpern in the 1940s, metal cable trays have become a staple in electrical installations. Their evolution has kept pace with the demands of modern infrastructure, from skyscrapers to industrial complexes and data centers. Cable trays remain a trusted choice for cable management due to their ease of installation, durability, and ability to meet strict safety standards.

Cable support systems are complex, with numerous factors to consider, including load capacity, environmental conditions, and regulatory compliance. For this reason, electrical engineers and contractors often rely on expert advice to select the appropriate type and size of cable tray and to ensure correct installation. A properly designed and installed cable tray system can enhance both the efficiency and longevity of an electrical installation, ensuring safety and reliability over the long term.

Future Trends and the Ongoing Evolution of Metal Cable Trays

As technology continues to advance, metal cable trays are also adapting to new requirements. The rise of smart buildings, renewable energy installations, and data centers has led to increased demand for efficient, scalable cable management solutions. Manufacturers are responding by developing more specialized cable trays that can support higher data transfer rates, carry larger loads, and accommodate increasingly complex cable layouts.

In response to environmental concerns, some companies are also exploring eco-friendly materials and production methods for cable trays. For example, aluminum cable trays made from recycled materials are gaining popularity, as they offer the same durability as traditional materials but with a reduced environmental impact. The future may also see the integration of intelligent monitoring systems within cable trays, allowing real-time tracking of temperature, load, and other critical parameters to enhance safety and efficiency further.

Conclusion

From Saul Halpern’s original wire basket invention to the versatile cable trays of today, metal cable trays have profoundly shaped the electrical industry. Their design evolution has provided electrical contractors and engineers with a reliable, efficient, and safe way to manage cables, making them an essential component of modern infrastructure. With applications ranging from residential and commercial buildings to complex industrial setups, metal cable trays continue to support the ever-growing demands of technology and construction.

As we look to the future, metal cable trays will likely continue to adapt to the needs of an evolving electrical landscape, proving once again that they are more than just a support system—they are a vital part of modern infrastructure, innovation, and design.

I have acted as a financial expert on the Today Show and Good Morning, America. I like to give reasonable advice on budgeting to people with any income level.